Mold Making Process

Mold making is a critical manufacturing process used to produce precise and high-quality components for plastics, automotive, medical, and consumer industries. Below is a complete step-by-step overview of the mold making process.

1. Appraisal & Valuation

Product requirements, material selection, tolerances, and production volume are analyzed to finalize feasibility and cost estimation.

2. Drawing & 3D Composition

Detailed 2D drawings and 3D CAD models are created to define mold geometry and structure.

3. Mold Flow Analysis

Simulation software analyzes molten material flow to detect defects before production.

4. CNC Machining

High-precision CNC machines manufacture mold components with accurate dimensions.

5. Mold Assembly & Inspection

All components are assembled and inspected to ensure correct alignment and operation.

6. Mold Testing

Trial runs are performed to verify product quality, surface finish, and cycle time.

7. Verification & Quality Check

Final inspection ensures compliance with customer and quality standards.

8. Final Approval & Delivery

The mold is approved, cleaned, packed, and delivered with documentation.

Mold Making Process Video

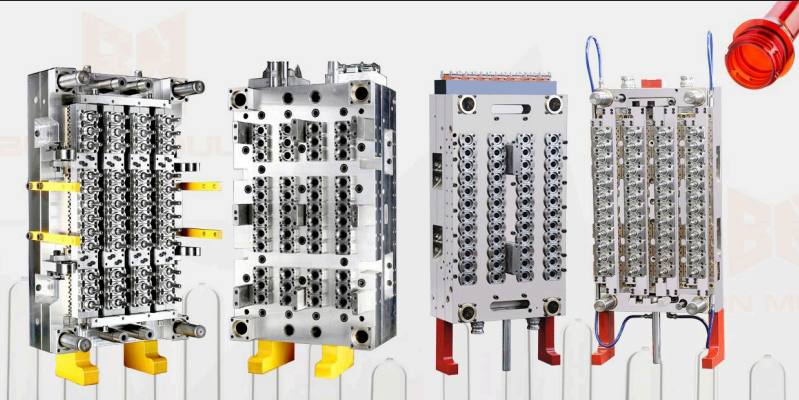

Our Molds